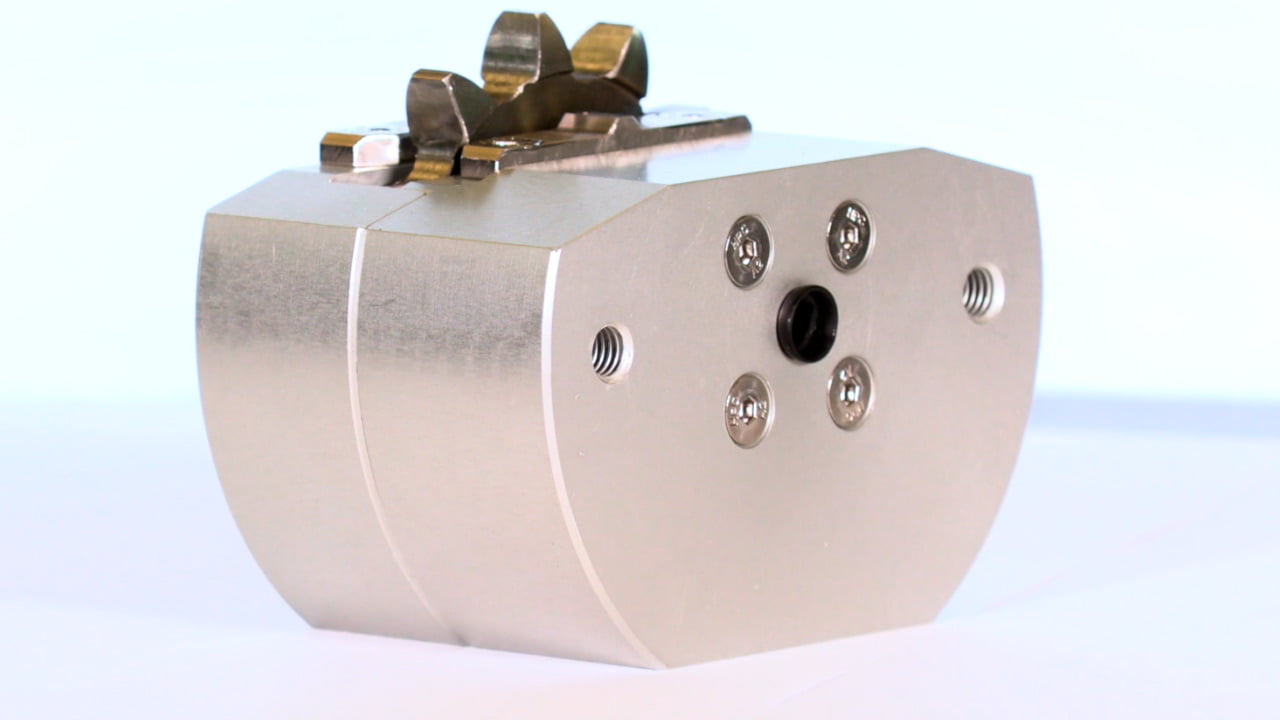

Product category: Oil dispenser

Chain: Step 1 Roller 25

Sector: Food, Packaging, other

Max temperature: 250 degrees

Strengths: The small size of this dispenser makes it adaptable even to confined spaces. It is easy to install, requires little maintenance and is completely automatic, if combined with one of our control units. It also ensures a lubrication process without any oil dripping. Ideal in the food sector, in particular in the presence of overhead chains, within small production lines, bucket elevators, packaging.

Description

Work safety: The manual chain lubrication process can be a risk factor for the operators assigned to it, since the chains must remain in motion throughout the operation. Furthermore, the chains are often placed in unsafe environments, at high temperatures and difficult to access. Our automatic lubrication not only reduces friction and wear on chains – when combined with the right lubricant, it also reduces noise levels and energy consumption. Working automatically, it also eliminates risks for operators and therefore constitutes an ideal tool for safeguarding health and protecting safety at work.

Our distributors are designed to carry out the lubrication of industrial chains automatically and independently, without polluting the product and in continuous operation. The “Gabry” distributor is capable of delivering the right quantity of lubricant on each component of the chain with extreme precision (links, pin and roller on both sides), without any oil dripping. It also offers the possibility of adjusting the adduction and pause times, thus optimizing the management of the system. It allows to oil several chains having different speeds and pitches at the same time and in a balanced way. It resists high and low temperatures (from -50 ° C. up to + 250 ° C.). It represents the ideal solution in all industrial sectors, which use chains as a force and transport organ.

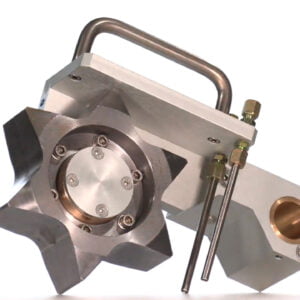

The “Gabry” distributors are able to operate in a temperature range varying from –50C° to +250°C. For those systems, where thermal expansions do not allow the installation of fixed fastening devices, the “Gabry” is fitted with a fastening swinging system, which counterbalances the movements caused by thermal expansion.

The “Gabry” is fed from a service cabinet with a customized tank and equipped with an electric min. level switch.

The service cabinets are supplied with a modular control system which includes distributors, pressure regulators, pressure gauges, time-adjustable solenoid valves and flow regulators for every distributor.

The lubrication and pause cycles of the system can be controlled in two ways: either by the PLC of the machine where the system is mounted, or from a special electric cabinet supplied by CEM. In both cases the system works automatically and independently to provide the required lubricant delivery schedule.

Wear and consequent chain elongation depend basically upon the lubrication and the operating life of a chain.