Product category: Lubrication of chains pitch 63, roller 47.6

Sectors: Food, packaging, other.

Applications: Lubrication of small industrial chains for the food sector, packaging, other.

Strengths: The distributors of this size are easy to install even where spaces are limited, light, low maintenance and fully automatic combined with our control unit. Ideal in the food sector, in small production lines, bucket elevators, packaging.

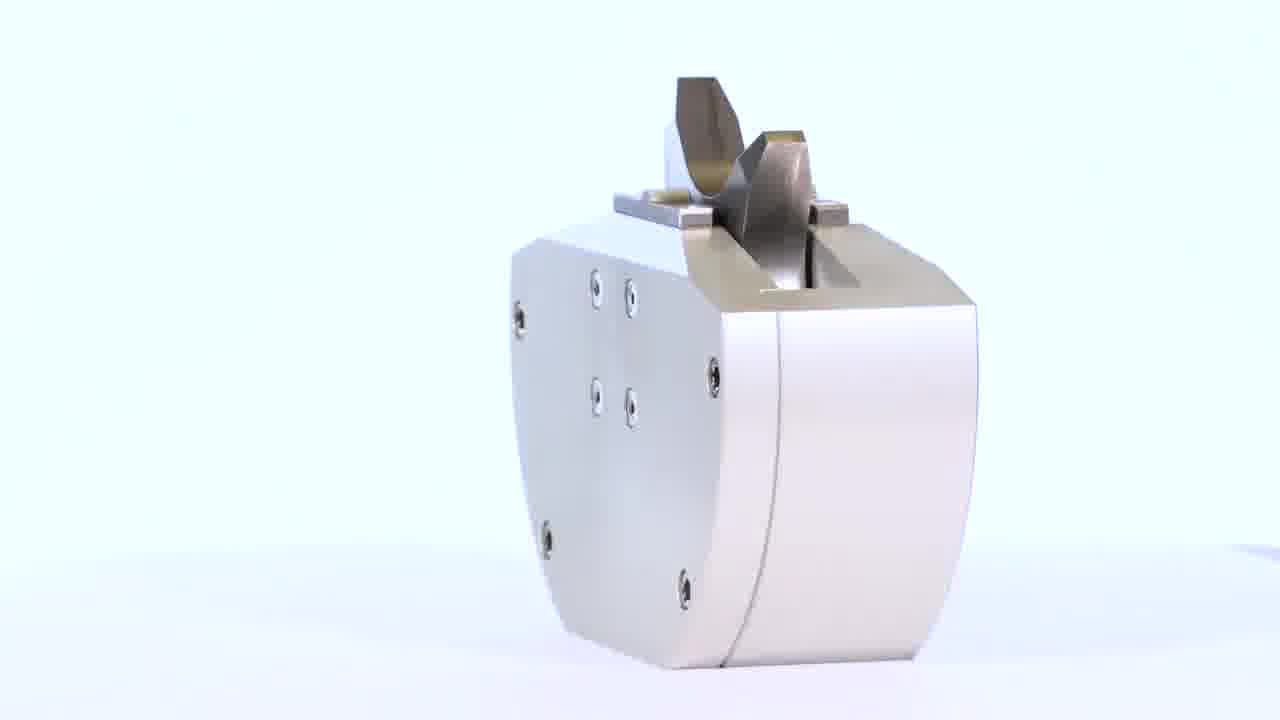

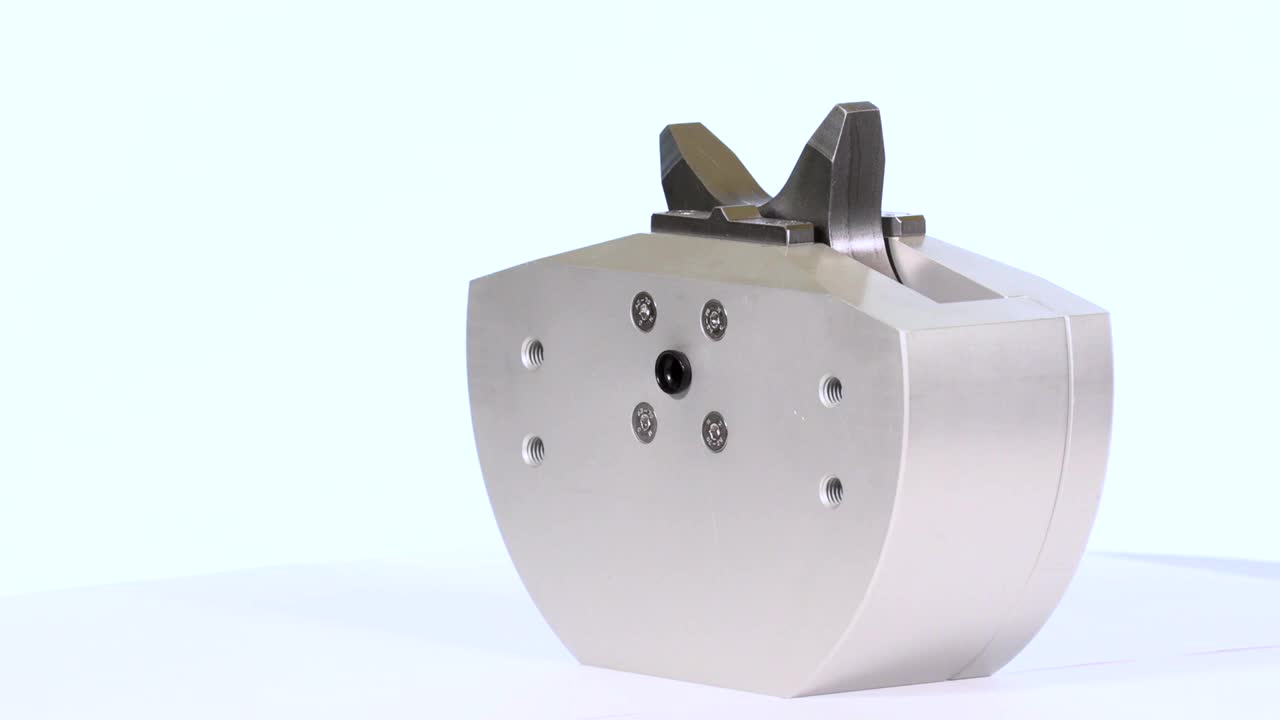

Description

Our distributors are designed to carry out the lubrication of industrial chains automatically and independently, without polluting the product and in continuous operation. The “Gabry” distributor is capable of delivering the right quantity of lubricant on each component of the chain with extreme precision (links, pin and roller on both sides), without any oil dripping. It also offers the possibility of adjusting the adduction and pause times, thus optimizing the management of the system. It allows to oil several chains having different speeds and pitches at the same time and in a balanced way. It resists high and low temperatures (from -50 ° C. up to + 250 ° C.). It represents the ideal solution in all industrial sectors, which use chains as a force and transport organ.

The “Gabry” distributors are able to operate in a temperature range varying from –50C° to +250°C. For those systems, where thermal expansions do not allow the installation of fixed fastening devices, the “Gabry” is fitted with a fastening swinging system, which counterbalances the movements caused by thermal expansion.

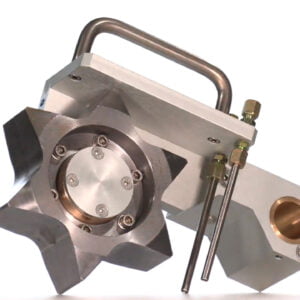

The “Gabry” is fed from a service cabinet with a customized tank and equipped with an electric min. level switch.

The service cabinets are supplied with a modular control system which includes distributors, pressure regulators, pressure gauges, time-adjustable solenoid valves and flow regulators for every distributor.

The lubrication and pause cycles of the system can be controlled in two ways: either by the PLC of the machine where the system is mounted, or from a special electric cabinet supplied by CEM. In both cases the system works automatically and independently to provide the required lubricant delivery schedule.

Wear and consequent chain elongation depend basically upon the lubrication and the operating life of a chain.